|

|

|||||||

| The Newbies Arena Are you new to knife making? Here is all the help you will need. |

|

|

|

Thread Tools | Display Modes |

|

#1

|

|||

|

|||

|

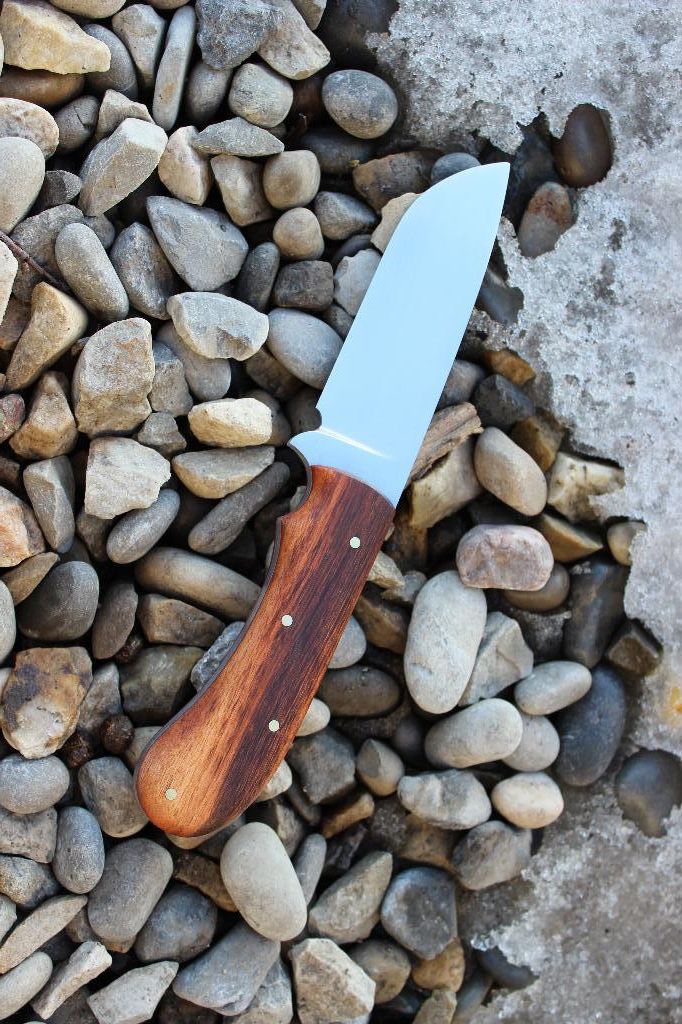

2nd Knife Done...Sheath pics added

Hi Everyone

Here's my second knife completed. I made it along side my first knife up to the point of heat treating. It warped when I heat treated it and I ended up annealing it and straightening before HT again. Anyway, here are the specs: 1084 Steel Blade: 3 3/4" Overall length: 8 1/2" Tigerwood scales with red spacers and 1/8" Brass pins Thanks for looking Brett [IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG]

Last edited by Bowman; 02-16-2013 at 12:56 PM. Reason: Sheath pics added |

|

#2

|

|||

|

|||

|

Awesome man! I really like that one. Great job.

__________________ J, Saccucci Knives, JSK |

|

#3

|

||||

|

||||

|

Looks real good! I like the pin placement.

|

|

#4

|

||||

|

||||

|

Very well done. All around good blade.

|

|

#5

|

||||

|

||||

|

Very nice and clean Brett.

Interesting that that blade warped on HT. Usually that geometry (based on pics & specs) is not very prone to warpage. Did you forge the blade or do stock removal? Either way, it is always good practice to normalize a blade a time or two before doing the actual hardening quench. We call it good foreplay in the smithing game. __________________ Carl Rechsteiner, Bladesmith Georgia Custom Knifemakers Guild, Charter Member Knifemakers Guild, voting member Registered Master Artist - GA Council for the Arts C Rex Custom Knives Blade Show Table 6-H |

|

#6

|

|||

|

|||

|

Thanks for the compliments everyone.

Carl, it was a stock removal blade and I'm not sure what I did to warp it but I hadn't normalized it the first time around. The second time I normalized for three cycles. Normalizing will now be a permanent part of the process. Thanks again. Brett |

|

#7

|

|||

|

|||

|

Added some Sheath pics

Here's the sheath I made for this knife.

Thanks for looking. [IMG]  [/IMG] [/IMG][IMG]  [/IMG] [/IMG]

|

|

#8

|

||||

|

||||

|

That's a really nice sheath, Brett!

|

|

#9

|

||||

|

||||

|

Brett,

The knife and sheath are top notch! I like the staggered pin placement, very nice touch. Keep up the awesome work! __________________ Stay away from fast women and slow horses |

|

#10

|

||||

|

||||

|

Nice work brett !!

|

|

#11

|

||||

|

||||

|

Nice work, Brett. Clean, simple and well executed. Nice work on the sheath, too! Great dyeing, I love the weave pattern. Is that a stamp? I've not seen this one yet. Keep 'em coming!

__________________ Chris K. Two Mountains Forge Delta, BC, Canada www.twomountainsforge.com |

|

#12

|

|||

|

|||

|

Quote:

Chris, The stamp is a triweave pattern; I think it's pretty well common. In my inexperience I fought with it a bit. I think at this point I'll be making knives for good. I can only hope to produce one of the quality and craftsmanship shown in your work and so many others on this site. Thanks again Brett |

|

#13

|

||||

|

||||

|

Turned out a nice package. The tri-weave takes some practice to build up a rythm, but looks good. A little gum tag boned into the flesh side of the leather before applying the finish will smooth the fuzzies down and lock them in place for a cleaner looking finish on the loop and throat of the sheath.

__________________ Carl Rechsteiner, Bladesmith Georgia Custom Knifemakers Guild, Charter Member Knifemakers Guild, voting member Registered Master Artist - GA Council for the Arts C Rex Custom Knives Blade Show Table 6-H |

|

#14

|

||||

|

||||

|

Sheath is as nice as the knife, well done. I really want to learn to work with leather. I keep saying that, but I'm so busy making knives I don't have room or time. When My new shed is built, I plan on giving it a try.

|

|

#15

|

|||

|

|||

|

Quote:

Carl I used gum trag on the throat but not on the belt loop flesh side. I did find that the belly leather I used was quite fibrous in places which made it difficult to burnish. In the future I'll be using shoulders. I'm curious to see how much better shoulders will be for sheaths. |

|

| Tags |

| awesome, blade, brass, build, carving, common, forge, handle, knife, knives, leather, lock, made, making, man, notch, package, pattern, scales, sheath, sheaths, simple, spacers, stock removal, temper |

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|