|

|

|||||||

| Register | All Photos | FAQ | Members List | Calendar | ShopStream (Radio/TV) | Search | Today's Posts | Mark Forums Read |

| The Newbies Arena Are you new to knife making? Here is all the help you will need. |

|

|

|

Thread Tools | Display Modes |

|

#1

|

||||

|

||||

|

Ebay Grinders

I saw the other day that several individuals are building belt grinders and selling them on eBay. I had considered building my own, but I'm not sure yet if I want to tackle that project. Most of them seem to be kmg type grinders if I understand correctly, and they are attractively priced compared to production models with similar features. One was $750 plus $50 shipping complete minus the motor.

I know it would depend on the builder, but I was just wondering if anyone had heard of someone buying a grinder from one of these sellers. They all seemed to have good eBay feedback. I guess my question is if there is anything in particular I should watch out for. Most have detailed pictures and descriptions, but to be honest I'm completely ignorant about these machines. What should I pay attention to as far as design, build quality, components, etc. The one I mentioned above was also built with an aluminum frame. Does this have any major advantage or disadvantage. |

|

#2

|

||||

|

||||

|

Hard to answer those questions without seeing the machines. How about a link or two to the auctions you are considering?

|

|

#3

|

||||

|

||||

|

Hi cbsmith

I haven't bought one on line, but I can tell you from looking at the specs of my grinder what seems to make the difference between even the brand names. Certainly the motor is a big part of the cost. If you're spending $750 on the grinder alone, how much more will a motor comparable to the one's which come with the commercially made models add to the price tag? I priced it out up here (Canada) once and the variable speed motor (DC) would have been $650 by itself. A variable speed console for a decent 1hp or 1.5hp AC motor would add as much, I'm sure. The moving parts are obviously the most important: what kind of bearings are they using on their wheels? Again, I priced these out once when I thought I would build my own, and there are big differences in quality and price. There is a lot of tension and pressure on these, and dust and grit will get into them eventually, so you want the best, hardest bearings possible (SKG is good), sealed on both sides. How does the tracking system work? Is it easy to adjust, and will it stay there once adjusted? How about the tension? What kind of spring are they using? will it keep consistent tension? How well are thw wheels balanced? Can you put different sizes on for different radii? Finally, I don't think an aluminum frame is necessarily a bad thing, if it is strong enough (thick enough) and the rollers are mounted properly. If there is any play or the weight rests directly on the aluminum arbor it may wear in one direction and make the whole thing unusable. I would install steel sleeves and press them into place before mounting the bearings. Just my two bits worth. Don't know if this helps at all... Cheers, Chris __________________ Chris K. Two Mountains Forge Delta, BC, Canada www.twomountainsforge.com |

|

#4

|

||||

|

||||

|

#5

|

||||

|

||||

|

Can't say that they look shoddy. Pretty sturdy looking work, and seemingly good workmanship. I would opt for easier adjustability, though. If you need a wrench for every change (table angle, platen angle, changing belts, etc.) you'll soon regret having a grinder which takes so long to change over - or you'll buy a second one so you can just step over to the other grinder and continue without having to change the set-up. A machinist will tell you that many jobs cost more for machine set-up than the actual job of making the part. I like to see knobs and levers which allow you to make changes easily and quickly, without the use of tools. The mount of the tool rest on the aluminum model seems a bit flimsy. It may have a hard time staying at the angle you've set - if you are inclined to use one... Also, I wouldn't want to work with a grinder that didn't have a variable speed set-up anymore, either. I guess I got spoiled.

__________________ Chris K. Two Mountains Forge Delta, BC, Canada www.twomountainsforge.com |

|

#6

|

||||

|

||||

|

CB,

Those both look like pretty good builds but I have to wonder why you are considering them at all. If there was a significant price difference between them and an equivalent KMG I could understand it but those two and the KMG are all the same price. For my money, in that case, I would definitely want Rob Frink's experience and warranty with the KMG. If you haven't already done so, check out this KMG: http://www.beaumontmetalworks.com/sh...aspx?itemid=11 |

|

#7

|

||||

|

||||

|

CBSmith, I would have to say the 2nd grinder you listed, with the steel tubing frame, looks a lot better than the first one.

On the first one I am leery of any aluminum pieces, either solid or not, that are threaded for bolts. The threads will always loosen up with use, and that work rest they provide looks rather small, flimsy, and held on by only one bolt with a washer. No wheel provided either. On the second one that of steel tubing. That flat work rest looks much better and can be turned around for use, and tilted nicely. That work rest also is much bigger, and provides better stability if grinding on an angle. But no wheel provided either. You can buy the basic KMG-PL for $750. I bought the 8" KMG Grinder for $920. That includes the flat platen, the work rest and an 8" wheel. You are going to want at least an 8" wheel. But they are currently out of stock of the 8" version. And to run on a 3 pulley system like mine you must get the 2 separate pulleys and a belt, an additional $90 or so. But, the KMG is a proven machine, and it is very heavy solid steel plate, and is a workhorse. But if you are contemplating the ones you see on Ebay, then just get the KMG-PL and get additional parts later. You will want the 8" or greater wheel and the small wheel attachment at a later date for sure. I contemplated all this same stuff and just said what the hell, I'll just make it hurt a bit and get the KMG. I am so #### glad I did! Good luck! And remember, you don't see used KMG's for sale. Just my 2 cents that could save you some headaches later! You will be out of $$$ either way you go. Tony Z Kansas City, MO __________________ ABS Apprentice Bladesmith USMC Veteran VFW Life Member "Retreat? Hell, we just got here!" Captain Lloyd Williams, USMC Battle Of Belleau Wood June 1918 |

|

#8

|

||||

|

||||

|

I guess I was just thinking the kmg was higher than that. I don't think I've ever seen it plain without a motor like that. I think when I've seen it in the past it was in a very expensive configuration. You're right it is the same money and probably a better bet.

I would love to have variable speed, but talking myself into saving for this price range is a stretch to begin with. I was saving for a Grizzly back before I lost my job and had to forget about it at the time. I just feel like the extra couple hundred is going to get me a lot more versatility in a machine like the kmg. Several hundred about that price range just isn't an option right now. Besides with a machine like this I can always upgrade later on right? Thanks for the advice. It really helped a lot. |

|

#9

|

||||

|

||||

|

You are correct about the added versatility of the KMG over the Griz and also about being able to upgrade the KMG in the future.

No need to give up on variable speed just because of the high cost of a VFD. Those basic grinders need to have a motor added, and a pulley. If you add a 3-step pulley instead of a single step then you have a poor man's variable speed at almost no additional cost. Most people, I believe, who have variable speed actually tend to use just two or three basic speed ranges anyway so a pulley system might be all you ever feel you need ... |

|

#10

|

||||

|

||||

|

Quote:

I have the 3 pulley set-up with a 1 1/2hp Baldor 110 motor. I run on the slowest speed because the other 2 faster speeds get me into trouble when grinding a bevel, plunge lines(!), or contouring certain areas on my handles or choil, ricasso areas. Takes a mere second and Bleep there goes hours of work, and the only way to fix is to grind that baby flatter or re-contour. So, slow is great for me, and required on the small wheel attachment. I do use the "high" and "higher" pulley speeds when I contour a blade"s profile, grinding forging scale off a freshly forged blade, sometimes grinding in initial bevels, getting a bar or tang thinner, flatter, or profiling a hidden tang. And that is when I am using my 8" wheel. I don't use my flat platen for that (glass face=chips easily). Also when using a Scotch-brite belt to remove surface rust, polish, etc. I do both forging and stock removal now, thanks to Ray and his recent Kitchen KITH. I will soon try a friends variable speed KMG out tomorrow, and I am sure I will like it, but I can't see anybody ever really needing variable over the 3 or 4 pulleys (yes they can be had) system. But in America anything that can make life easier is a hot commodity. So, luxury is nice, but not required. If you have to turn a variable down to a speed below the slowest speed on my lowest pulley then you might as well just go get a file! If somebody can honestly convince me why I need a variable over multi-pulleys or how I will make a better knife with a variable versus pulleys please chime in. I can get one if I want, but I am not sold yet. And I am just a serious hobby maker, not trying to earn any kind of living out of it. Just my 2 cents. Tony Z Kansas City, MO __________________ ABS Apprentice Bladesmith USMC Veteran VFW Life Member "Retreat? Hell, we just got here!" Captain Lloyd Williams, USMC Battle Of Belleau Wood June 1918 |

|

#11

|

||||

|

||||

|

[QUOTE=

If somebody can honestly convince me why I need a variable over multi-pulleys or how I will make a better knife with a variable versus pulleys please chime in. I can get one if I want, but I am not sold yet. And I am just a serious hobby maker, not trying to earn any kind of living out of it. Just my 2 cents. Tony Z Kansas City, MO[/QUOTE] Oh, but once you've tried it... it's like sex and chocolate... there's no going back! No, seriously, you are right. There is no reason why you would all of a sudden turn out better knives just because your machine has a variable speed control. It's just convenience and ever so nice to just turn the knob to go faster or slower. And Ray is right, most of us work at only a couple of speeds - I tend to go from 25% to about 60%, not very often at 100% unless I have some major removal to do, but it sure is nice to have these options. CB I hear you on the cost part, though. It took me four years to part with the cash for the 2x72 I have now. Hang in there, it'll come in good time... __________________ Chris K. Two Mountains Forge Delta, BC, Canada www.twomountainsforge.com |

|

#12

|

||||

|

||||

|

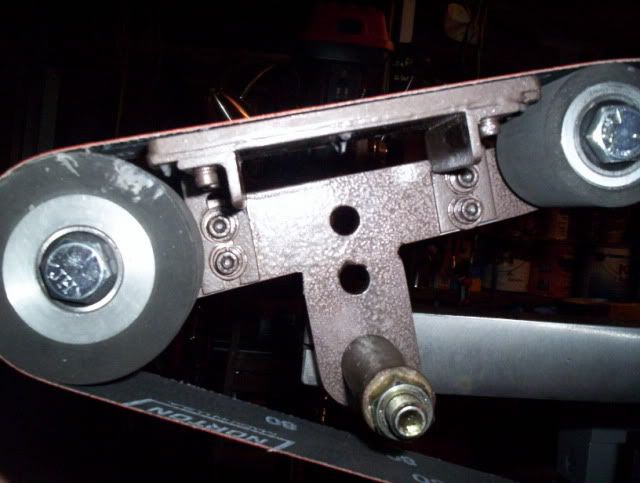

Anyone can build something that looks like a grinder! Having said that I will say I built my own KMG clone.

The grinder and how well it works is all in the precision of the build. There is a reason that the KMG costs what it does. The precision of the machine is what makes the Beaumont KMG such a quality machine. That man has many $ worth of machines with that cut the parts for a KMG grinder, and that is why he turns out such a quality machine! I knew when I built my own that I had to keep it as precise as I could with the tools I had to work with, and after I put it into operation I have had to go back and make tweaks to it to get everything like I wanted it to work. My platen is now in it's third version. My machine was built with a drill press. Which was pretty much the only precision type tool I had to work with! Here are some pics of mine while being built.  This is version one of my platen. I decided right away it was too short! Plus as you can see the mount was in the way of laying the platen down to a flat postion!  This is version two of the platen. It wasn't true.  When I tracked the belt to get it too run straight at the platen, the belt was way off the power pulley as well as the tracking pulley. You can actually see in the pic if you look at the belt adjustment pulley how much I was having to run the belt off to the side to compensate for that problem. The (perfectionist) in me could not stand too see it run like that so I had to go to work on it! Version three which I don't have a pic of fixed that. I went back and fixed the holes that were tapped for the wheels and stretched out the length of the platen, to the longest version yet. That is what I am talking about as too precision. One of the holes for the wheels on my platen was tapped just ever so slightly off. The result made the wheel lean, not enough to visible to the eye but just enough to make the belts not want to track! There is no way, knowing how I tried to maintain control quality on my own build, that I would buy one off of Ebay unless I knew the guy doing the build or had very good references to one of his machines. Like it has been said you can buy the basic unit and if you will watch for motors on Ebay then you can power it with pretty much the same unit that Rob at Beaumont uses. He is a stand up guy and when I built my own clone he knew I was doing a build of my own still answered any question put before him. He has nothing to fear as you will be hard pressed to build one with as much quality built into the machine as one of his because you ain't got several $100,000 worth of equipment to do the cutting and assembly as one of his! If you do your own and shop around you can come out cheaper. However if you don't have the knowledge to and tools to do your own build and you have to buy everything. I doubt you will have less in the machine you end up with than if you bought the unit outright from Beaumont! And NO I don't work for the guy, I don't even have one of his machines! I can just appreciate the quality of one of his machines, and from anything I have heard he is stand up, top shelf when it comes to problems with the machine. __________________ C Craft Customs With every custom knife I build I try to accomplish three things. I want that knife to look so good you just have to pick it up, feel so good in your hand you can't wait to try it, and once you use it, you never want to put it down ! If I capture those three factors in each knife I build, I am assured the knife will become a piece that is used and treasured by its owner! C Craft Last edited by C Craft; 05-04-2014 at 09:10 AM. |

|

#13

|

||||

|

||||

|

If I were going to buy one of those, Steel is Real! The Aluminum one looks really nice, well made and high tech. The problem is weight. I work on machines made of that same extruded aluminum and it is very strong but scary light. I am thinking of vibration, which would not be a problem if everything was balanced.

|

|

#14

|

||||

|

||||

|

Yeah, I'm pretty much over the idea of the ones on eBay. You just reinforced most of my anxieties about building my own. I am a decent hand at building and assembling things, but I have limited tools and time. I have no doubt I could do it, but I doubt I would save enough to make it worth while, and I would rather spend the little free time I have practicing my grinds once I get the cash to get started.

I also glanced at the coote grinder. I'm really not leaning towards it, but I do wonder if it would be a little better than the grizzly if I decide to go just a little cheaper. I believe I will just set my goal for the basic kmg and grow from there though. Thank you all. This was the exact type of first hand info I needed. |

|

#15

|

||||

|

||||

|

The Coote is a little better than the Griz in terms of build quality and the potential for making it variable speed but, aside from that, it suffers from the same limitations shared by all two wheel designs. But the really bad part is that by the time you get it set up you will be right back in the same price range as the basic KMG and its eBay clones. So, the Coote can have some advantage over the Griz but it has no advantage at all over the KMG ...

|

|

| Tags |

| advice, angle, arbor, bee, belt, brand, build, building, design, easy, for sale, forge, grinder, grinding, made, make, making, motor, mount, project, shop, steel, tools, what kind, wheels |

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

| Thread Tools | |

| Display Modes | |

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| grinders | claymoore | The Newbies Arena | 7 | 01-19-2013 09:04 PM |

| Grinders | Doug Lester | The Newbies Arena | 14 | 04-01-2008 02:52 PM |

| Grinders | Waycasy | The Newbies Arena | 10 | 12-06-2003 11:29 AM |

| Grinders | Tbonz | The Newbies Arena | 2 | 10-09-2003 07:12 PM |

| Grinders | honour | The Newbies Arena | 2 | 09-25-2003 06:44 PM |