|

|

|||||||

| The Outpost This forum is dedicated to all who share a love for, and a desire to make good knives, and have fun doing it. We represent a diverse group of smiths and knifemakers who bring numerous methods to their craft. |

|

|

|

Thread Tools | Display Modes |

|

#1

|

||||

|

||||

|

3 quenching, what for?

I`m reading Ed Fowler's Knife Talk, and I wonder....

Why he make 3 quenching on 52100 blades? I make a single quench and the blades works more than well. I ask because I,m thinking about entering in the ABS. What you thinks? Saludos Mariano |

|

#2

|

||||

|

||||

|

I have done both single and multiple quench on several different types of steel. I did not notice much difference if any. Both my test knives were done in the single quench and performed admirably. I made one competition knife from 52100 and single quenched it and tempered 3 times and won the competition. After the cutting the knife was still hair popping sharp. So if you want to join the ABS, you do not need to do multiple quenches.

Chuck __________________ http://www.woodchuckforge.com Avatar, Scott Taylor Memorial Scholarship Knife Photo by Bob Glassman Chuck Richards ABS J.S. |

|

#3

|

||||

|

||||

|

__________________ http://www.woodchuckforge.com Avatar, Scott Taylor Memorial Scholarship Knife Photo by Bob Glassman Chuck Richards ABS J.S. |

|

#4

|

||||

|

||||

|

#5

|

||||

|

||||

|

Quote:

|

|

#6

|

|||

|

|||

|

I agree with Chuck, triple quenching is NOT necessary,... and very risky.

From what I understand some smiths practice triple quenching to achieve a more refined grain structure. However, it may cause more damage to the steel than good, regardless of the grain size or refinement. Multiple quenching for the purpose of grain refinement is not correct. Quenching is simply to harden the steel. |

|

#7

|

|||

|

|||

|

The main thing to remember about 52100 is that it is highly susceptible to ?embrittlement from over heating? in the hardening cycle, like D2 and some others.

I recommend a single edge quench on 52100, being careful not to over heat it. |

|

#8

|

||||

|

||||

|

Blades with a complete quench can pass the ABS testing. You need to be sure to draw the spine back to at least blue but not the edge. The blade that has a crack in it on your knives above, may not have passed since the rule says it may crack up to 2/3 of the width of the blade. I do not recommend full quench. Edge quench is much more forgiving IMHO.

Now why go with 52100?? It is much less forgiving in a the whole process than 5160. My JS test knife was 5160 and I had no problems. I have made several knives I tested per the ABS requirements and all passed with 5160 even an MS practice test knife from 5160 and 15N20 passed. It is easier to get and much easier to forge and HT. Chuck __________________ http://www.woodchuckforge.com Avatar, Scott Taylor Memorial Scholarship Knife Photo by Bob Glassman Chuck Richards ABS J.S. |

|

#9

|

|||

|

|||

|

I also think the edge quench is a better choice. The only worry I have with the blue draw on the back, is with the possibility of "temper embrittlement", at temps., above 500 in the so called "blue brittle range".

You might have to do a little more research, but I believe the "embrittlement from over heating" with 52100 is different than embrittlement from grain growth and more akin to quench and temper embrittlement. The triple draw should be O.K. as long as you haven't over heated it or caused any type of quench embrittlement. Sometimes the embrittlement doesn't show up until the temper. It can show up in the as quenched state and at tempering temps., below that which are normally considered safe. I think 52100 is a very tough steel, but I?ve never been that crazy about the ?edge?. I used to play around with it when I had the power hammer and controlled electric furnace. I think there are better choices for a simpler shop set up. 5160 should be fine and as Chuck said, more forgiving. |

|

#10

|

|||

|

|||

|

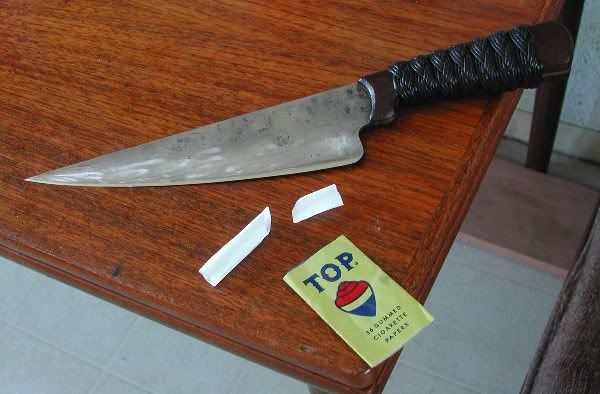

You can pass the A.B.S. tests with a knife that is just "shaving sharp".

I've finally divided degrees of sharpness down to a little backyard scale: #1. Shaving sharp= almost sharp, but kind of dull. #2. Scary sharp= a little sharper than shaving sharp. #3. Popping a 1/2 inch diameter hair loop= sharp enough. #4. Cleaving a standing hair= tree top sharp. #5. Cleaving a free standing rolling paper tube= 9th chakra sharp!    ... of course if you breathed on it a few times when it's "9th chakra sharp", the edge would most likely oxidize off... What I wonder is how many cuts you can make through a one inch manila with a "9th chakra sharp" edge and still be,... "9th chakra sharp"? For that easily attainable "tree top edge",( though not as tough as 52100 or 5160), I like W2 and 1095.  We have to look at what industry uses these alloys for from a "historical" standpoint. 52100 is bearing steel! Last edited by Tai Google; 11-02-2006 at 12:12 PM. |

|

#11

|

|||

|

|||

|

I have a few?

How good does a knife really need to be? What should a knife be capable of doing? |

|

#12

|

|||

|

|||

|

Quote:

Hey! ... I want my knife to cook me breakfast.

|

|

#13

|

||||

|

||||

|

A japanese Chef ones say to me "a sharpened knife does not cut ......separates" jajajja

Chuck, the blade in the photo crack after bending 2 times to 90?. If I joint the ABS I have to wait 2 years before take the JS test, is that right? Thanks to all! Saludos Mariano |

|

#14

|

||||

|

||||

|

I've been watching a DVD on a guy that uses 52100, and quenches in water. The tape goes on to show it. It's Charlie Ochs (M.S.) "Forging and finishing the Ox Forge Special Operations Bowie". I have found it to be a good DVD. Charlie apparently has good results with the way he treats his 52100. It's (the DVD) inspired me to give it a try in a few days, just to say I've done it. I'm betting my 52100 blade shatters like a windshield being hit with a sledge hammer when it hits that water. He doesn't say anything about how much heat for the steel or the water(looks like no heat for the water), but does that part by eye, but again, it must be right for him. From the time he pulls the blade out of his gas forge, until it touches water is about 2 seconds. It stays completely submerged for another 2 seconds, then comes out, and that's it, that's the quench. Temper is via a toaster oven. I recommend the tape or DVD. Charlie seems to be a no frills down to earth common sense sort of guy, it was fun to watch. Didn't mean to get of topic here, but was showing another view of 52100 and it's quenching medium. I think you'll like it, I did.

Last edited by rhrocker; 11-02-2006 at 08:06 PM. |

|

#15

|

||||

|

||||

|

Once you join the ABS you must wait 3 years prior to taking the JS fit and finish presentation. Tis means you can take your performance test after 2 years. You can cut a year off this time if you take the basic bladesmithing course at the ABS school.

If your blade cracked on the second bend then it would have passed, so long as the cutting and edge holding requirements were maintained. A agree with Tai's asessment of blade materials. There is no Magic Steel, I have yet to try w-2 and will be shortly but 1095 gets very very sharp. My MS test blade was 1095 and 15N20. The practice blade I made from the same billet performed the cutting very well then did 9 1/2 180 degree flex's before it cracked. My actual test blade performed much better than I could have wanted. Does the multiple flex's make for a better blade? i don't feel it does but rather tests your ability to do the process as called for. Like many others have pointed out if it cuts like you want it to then use the steel you are comfrotable with. Some wll swear by 52100, others swear by W-2 or O-1 or CPM ---. As mentioned in other threads test your blades. Only then will you know how they will perform. Tai's rolled up cigarette paper cut is an awsome test of edge geometry and keeness. Cut different stuff and see what the blade material does. Practice before going for the test. Make sure the knife you take will perfrom the first two steps of rope and 2x4 cut. I made 4 practice knives for JS and 2 for MS. Good luck and keep on cutting Chuck __________________ http://www.woodchuckforge.com Avatar, Scott Taylor Memorial Scholarship Knife Photo by Bob Glassman Chuck Richards ABS J.S. |

|

| Tags |

| blade, forge, forging, knife, knife making, knives, switchblade |

| Currently Active Users Viewing This Thread: 1 (0 members and 1 guests) | |

|

|