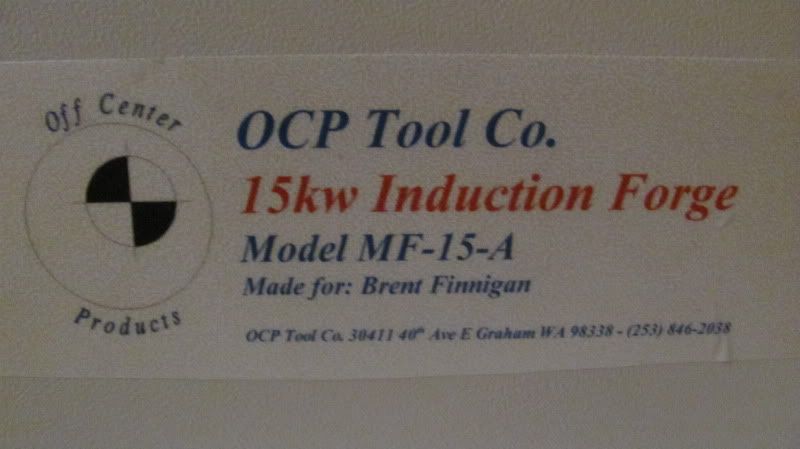

I have been wanting to get one of these for a couple years and finally went for it. It still needs the Dynaflux R1000 cooler which should be in by Mon. Grant Sarver of Off Center Tools is the dealer for them and only lives 30 minutes from me. He has been very helpful in showing me all the bells and whistles on it.

It uses 220vt at about 40 amps and the cooler uses 110vt. Since my shop is not heated I will use the anti-freeze coolant for it. It comes with a foot pedal and three different sized coils. Grant has shown me several other coil configurations that can be easily made with copper line.

For those of you not familiar with induction heating put simply it's similar to a microwave oven except for metal. It will heat both ferrous and non ferrous metals as well as graphite.

The advantages of an induction forge are:

No propane to buy at $3 a gal here.

No lugging tanks back and forth to be refilled.

Here in the PNW power is cheap.

It does not heat up the shop since only the steel gives off heat.

Pinpoint heating allowing some unique forging possibilities.

Far better heat control and monitoring steel color.

Mokume and pattern welding will be more precise.

The coil can be operated inside and inert gas environment vastly reducing oxidation.

It's programmable for both power level and heat time allowing precise consistency in repetitive tasks.

The ability to cheaply and easily make specialty or custom coils to fit a given task.

Faster initial heating and even faster re-heats.

Can be kept closer to your anvil or stake vise.

No insulation refractory to maintain/replace or particulates to breath.

No CO/ventilation concerns.

Quiet operation.

This is not my video but it shows how fast it heats steel.